Quality

Quality

Engranajes GRINDEL S.A.L. has been striving for more than a decade to achieve absolute quality in its processes and products, positioning the company as a reliable international supplier.

Each stage of the process, from the review of the quotation-sales order, design, purchase and receipt of materials, the supervision of suppliers and the subcontracted operations, manufacturing in all of its stages, including the final control and shipping, is reviewed and controlled in accordance with the most demanding internal procedures and specifications of the Quality and Environmental Management System under the ISO 9001 and ISO 14001 Standards.

Industrial and quality management processes are subject to continuous revision and improvement while continuously performing internal and external audits by clients or other regulatory agencies.

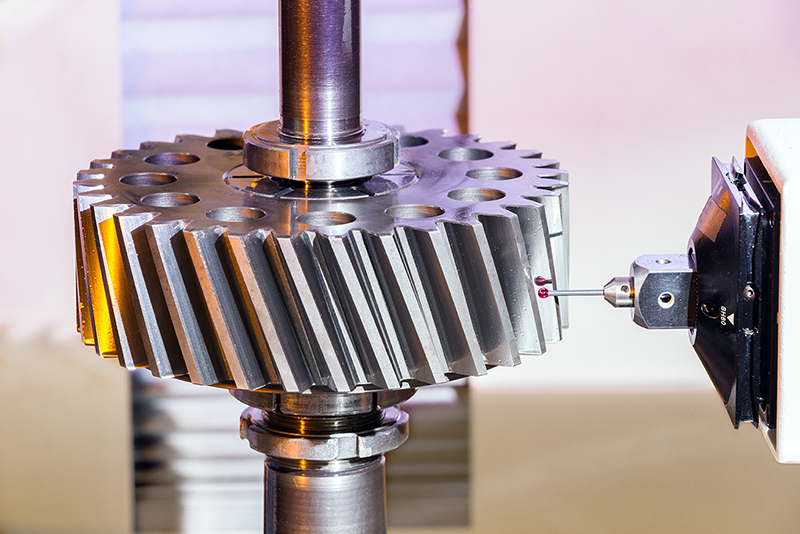

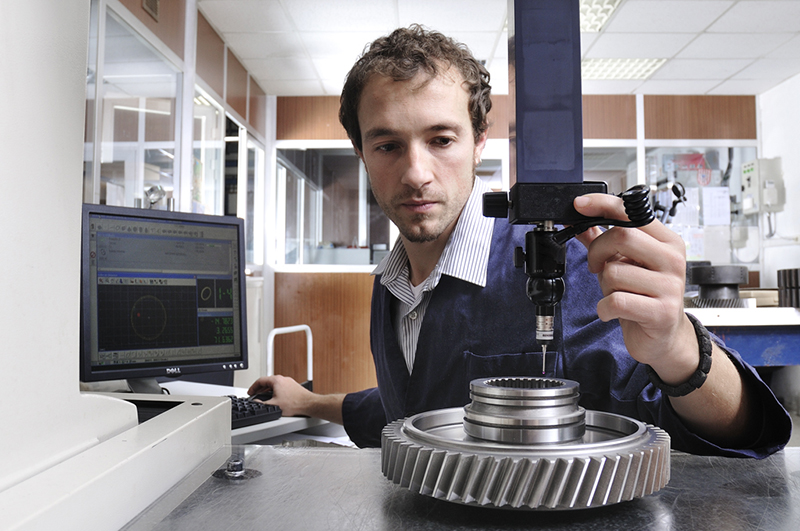

In addition, in order to ensure the overall quality of the cylindrical gears and splined shafts under the DIN, ISO and AGMA Standards, among others, Engranajes GRINDEL S.A.L. has well-trained and qualified technicians and we are equipped with the most modern quality control equipment, including the following:

- Three-dimensional ZEISS Accura II 9.12.8

- Gleason CNC 650 Analytical Gear Inspection System

- Three-dimensional Mutitoyo

- Magneflus Crack Analyser

- Error analyser consisting of Mahr rolling machine

- Setting up of NITAL Tests

Finally, at Engranajes Grindel S.A.L. with each request we deliver the Certificates of material, heat treatment, dimensional report as well as the evolute and profile graphics.